Hercules Laminated Elastomeric Bearing (HLEB)

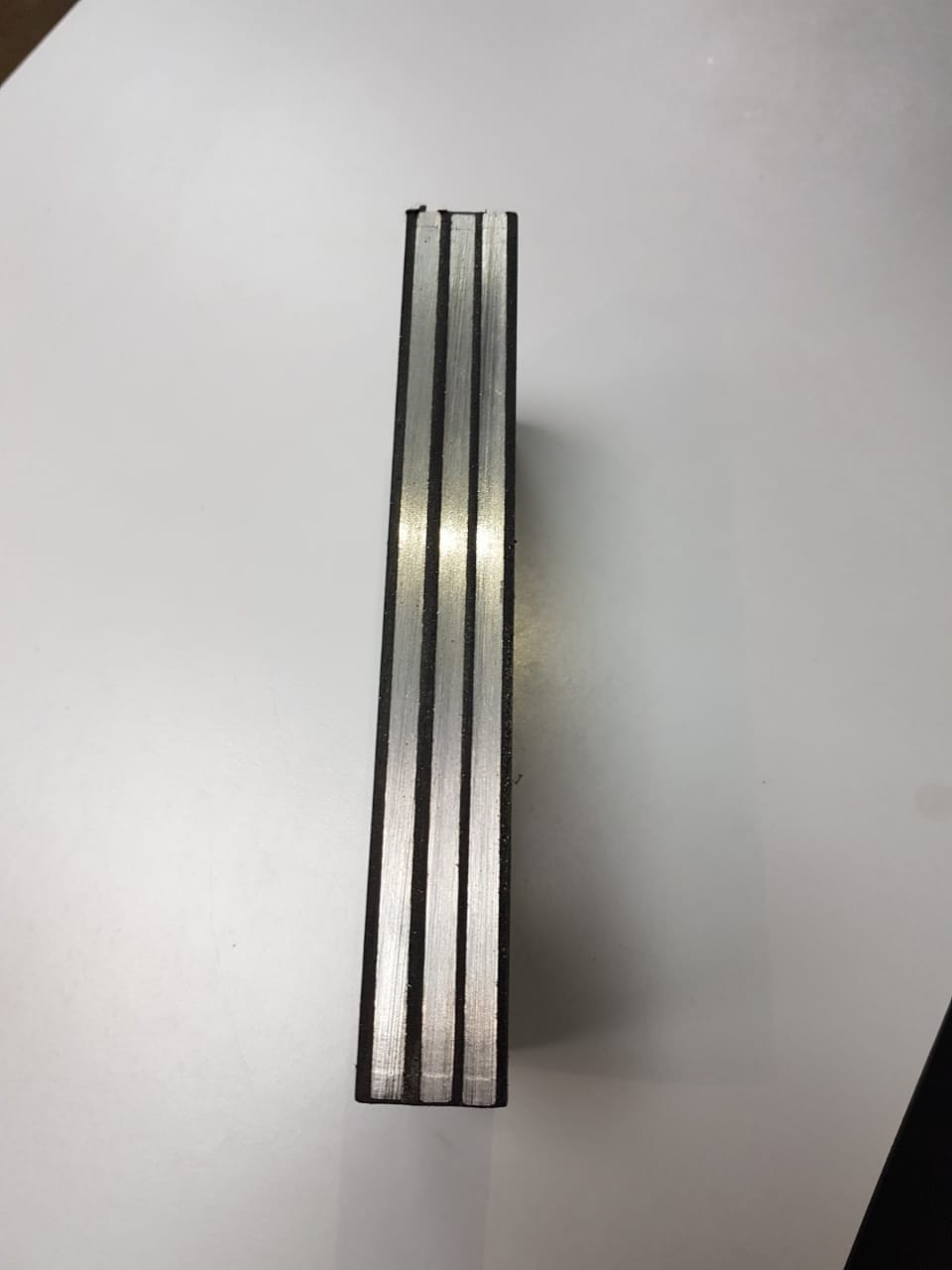

HERCULES Laminated Elastomeric Bearings are engineered using either Polyisoprene (NR), Polychloroprene (CR) or High Damping Rubber (HDR), selected based on the specific performance needs and environmental conditions of each project. With a proven international track record spanning over 50 years, HERCULES bearings are trusted globally for their exceptional strength, flexibility, and long-term reliability.

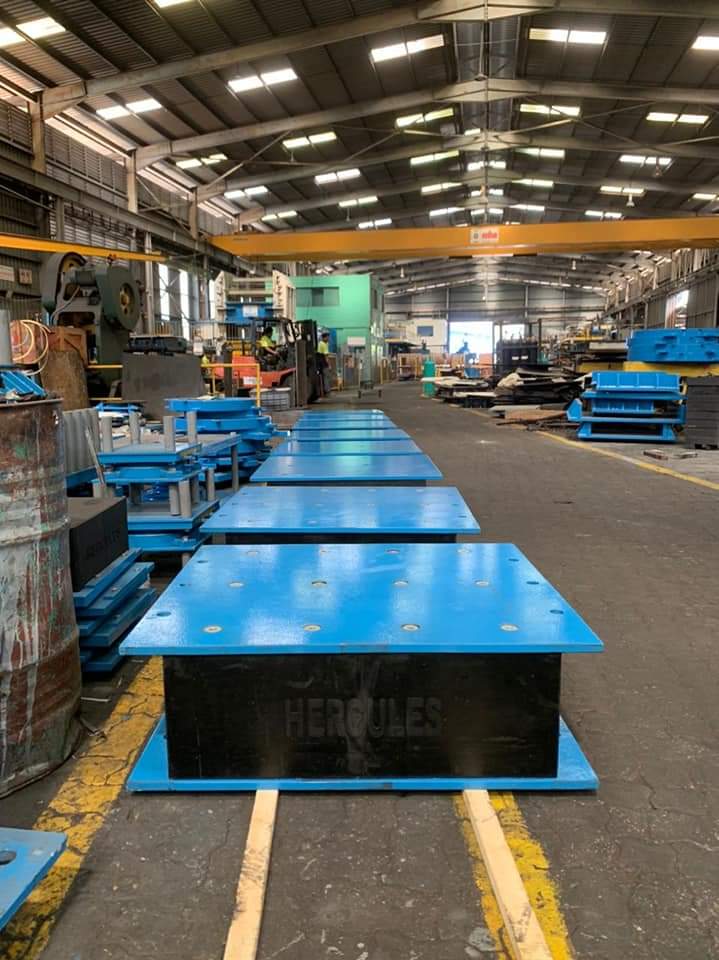

HERCULES bearings, while extensively used in bridges, are increasingly specified in a wide variety of structures that require load transfer, vibration isolation, or function as an earthquake damper. These include building structures, parking garages, heavy industrial machinery, storage tanks, and pipe supports, showcasing the versatility and adaptability of HERCULES rubber technology across multiple sectors.

HERCULES manufactures its elastomeric bearings in full compliance with EN 1337-3, and holds CE certification under Certificate No. 071-1337-3-CPR-0986, confirming their suitability and performance for use in critical infrastructure around the world.

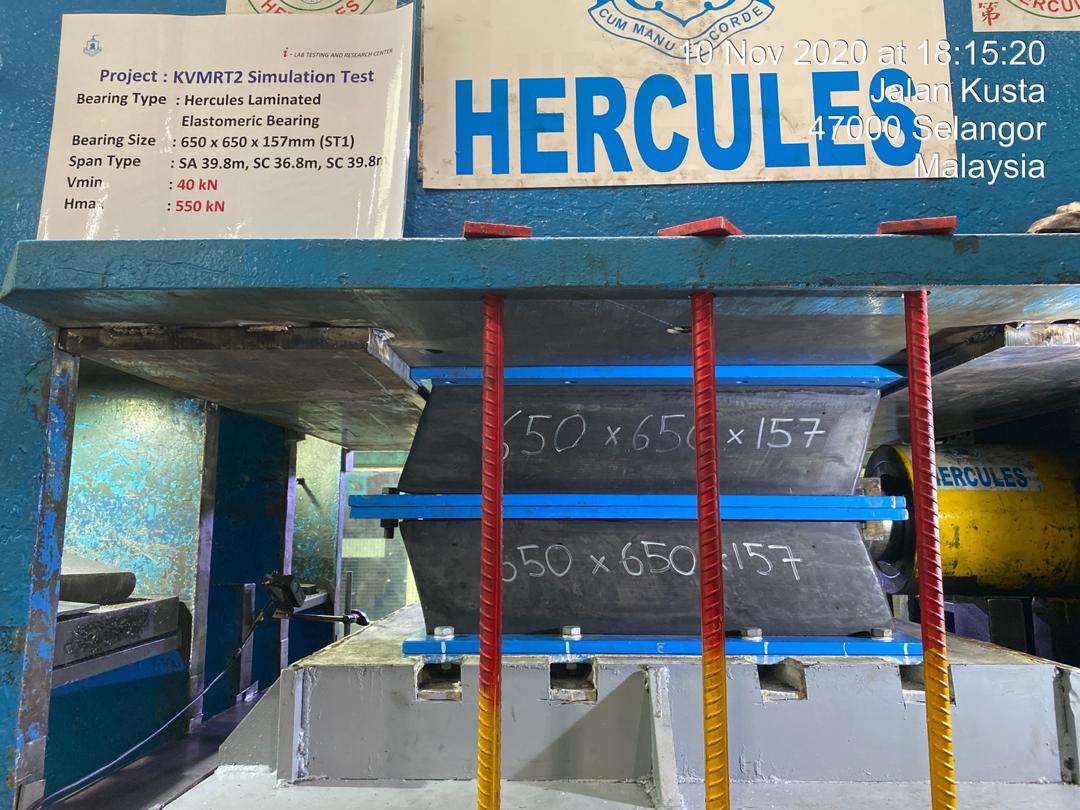

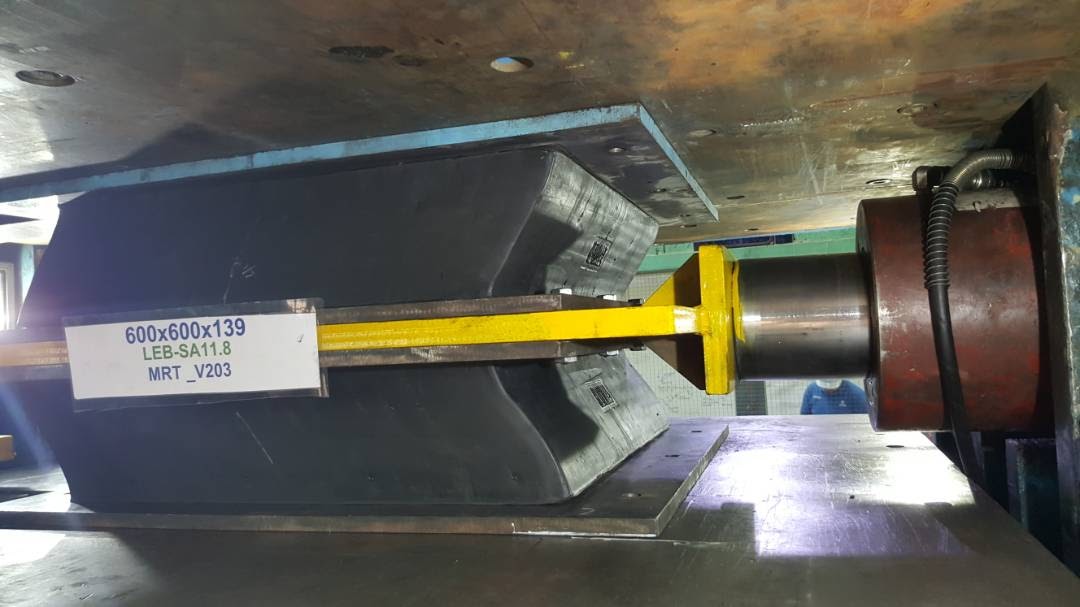

HERCULES is fully capable and well-equipped to manufacture bearings in all sizes, including large units up to 2 meters wide and 1 meter high. We also carry out all the required load tests, physical property tests, and chemical analysis to ensure quality. Testing is done according to major international standards such as JIS, ISO, ASTM, AASHTO, AS, IRC, EN 1337, EN 15129, and others.